CERAMIC GLAZES

Not all glazes are transparent and colorless. There is a wide variety of textures and colors depending on the materials and the cooking treatments. Transparency can be considered the normal state, because if a glaze is fired to maturity and all its oxides reach the fully melted state, it will normally be clear and transparent.

A fully melted glaze is prone to having a high-gloss surface. This is because the glaze levels and flattens when it melts, forming an extraordinarily smooth surface. This homogeneity is one of its practical characteristics, since a uniform surface is hygienic as it is easy to clean.

The surface of a ceramic piece must meet certain requirements, resisting certain demands in its use (wear, thermal shock, acid attack, etc ...), in addition to presenting an appropriate decorative effect for ceramic work.

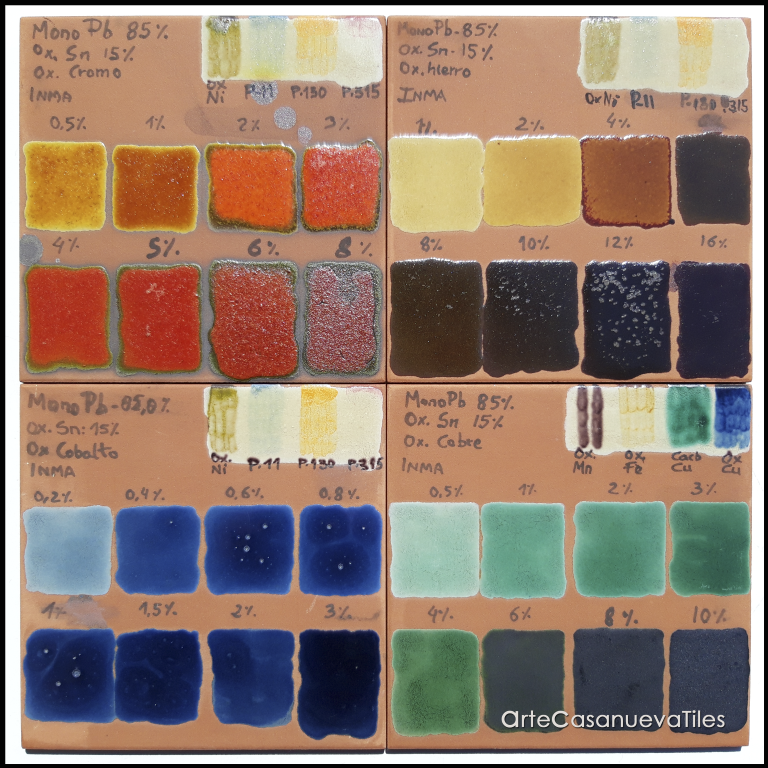

The task of calculating the formulas and composing the recipes results from mixing the raw materials in the appropriate proportions, that is, the oxides that forms the glazes, grouped into refractories, fluxes, opacifiers and colorants.

Ceramic glaze is a vitreous (liquid) or semi-vitreous, transparent or opaque, glossy or matte, colored or colorless layer that is applied on ceramic pieces for functional and / or decorative reasons, then they undergo a firing process until they acquire the characteristics desired, of color, texture, resistance, etc...

Ceramic glazes are made up of selected materials, prepared with appropriate doses and mixed, to which water is added and applied to the surface of fresh or bisqued (fired) pieces, covering them. This mixture, when fired in the Kiln at the usual temperature ranging between 700 ° C and 1350 ° C, forms a glassy paste that adheres to them.

In the preparation of the glaze, several elements are used, two of which are essential: the vitrifier (silica: refractory) and the flux (a lead compound, alkaline, or borax). The union of these materials produces a transparent, colorless and shiny glass.

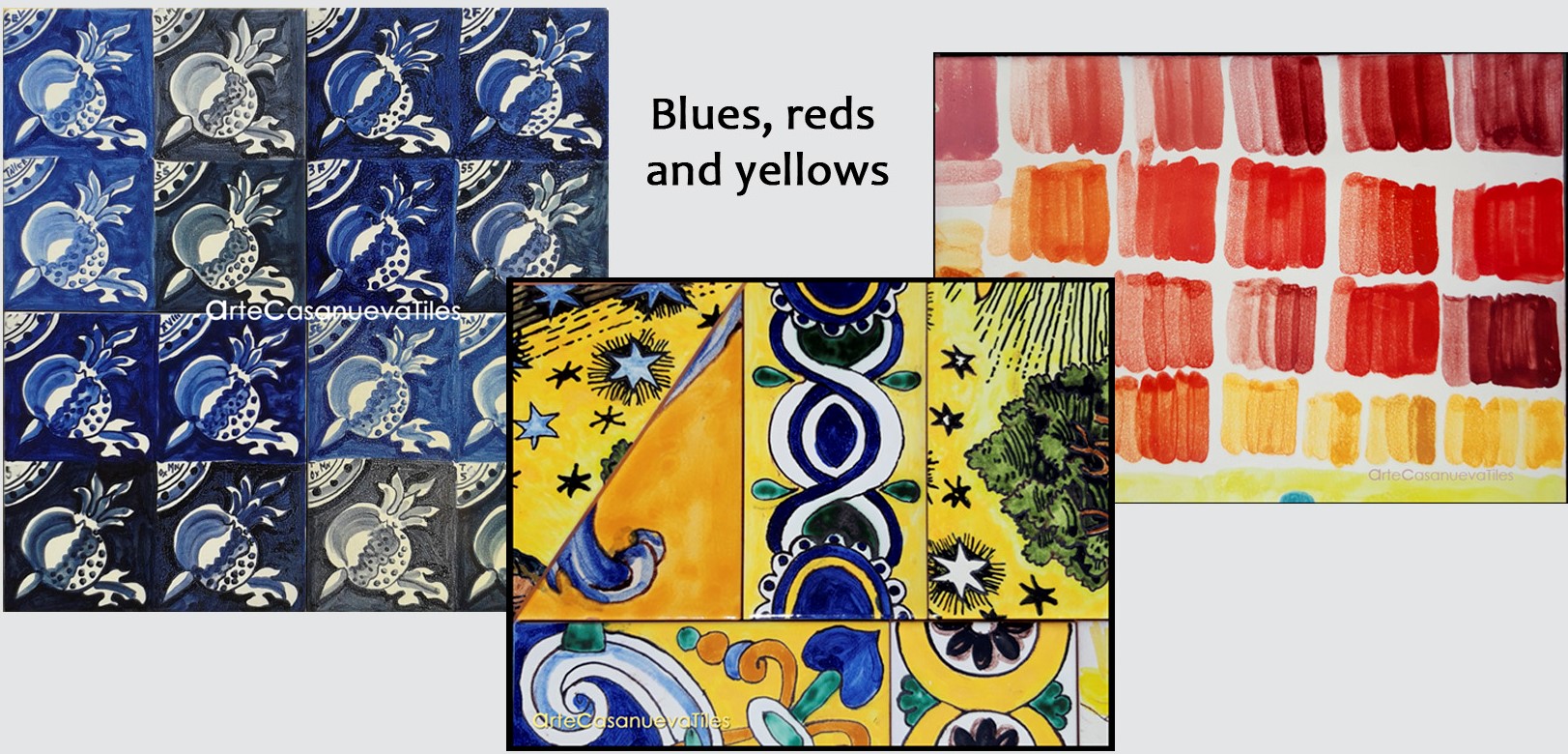

COLOR PALETTE

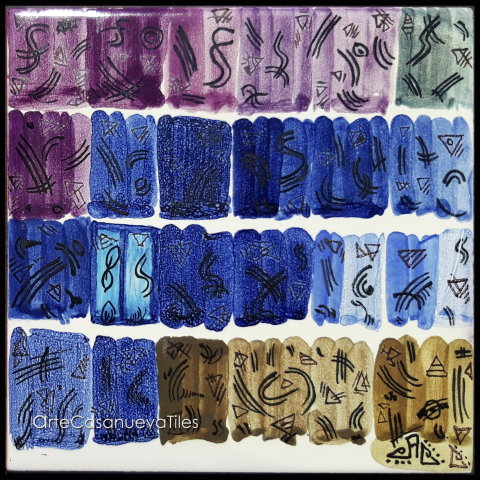

In a r t e c a s a n u e v a All the tiles and murals are painted with a palette of a wide range of own colors that allows to obtain a different and original color. A luminous finish adaptable to all environments.

To achieve the desired color tones and textures or effects many tests are necessary for each job until a good result is obtained.

In the workshop both are used already prepared glazes and also glazes that are specially made to obtain textures or tones appropriate for the work to be done.

In order to achieve all the tones required by the personalized projects and designs developed in the workshop, it is necessary to carry out many formulas and mixtures to get a great variety of colors and textures and to choose the best one for each case. The decorative technique to be used must always be taken into account since the glazes change depending on whether it is for cuerda seca (dry line), majolica, azulejo de arista (edge tile) or any other.